Parts CatalogEverything But the Can

Covers

Standard dust and patented tamper-evident covers are a great solution for your products.

Custom Dispensing Systems

Dispensing 2 component systems, industrial reusable applicators, disposable applicators and more.

Barrier Packaging

Pistons and barrier package options are designed to provide a unique dispensing solution.

Formulation Development

Clayton's Engineering Team can help you develop custom formulations for your products.

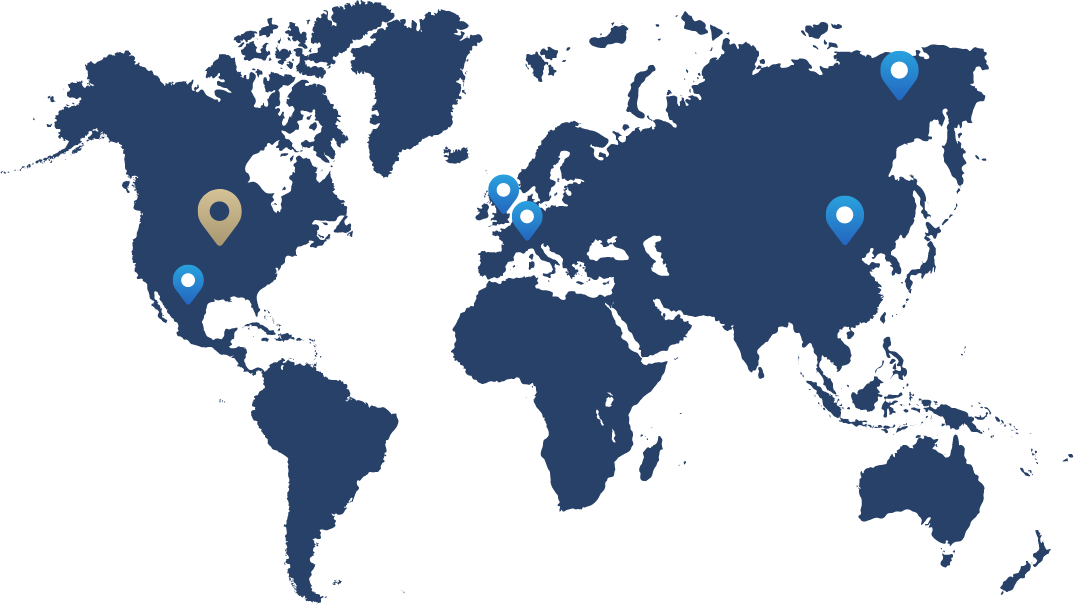

United States - World Headquarters

866 Horan Drive

Fenton, MO 63026, USA

MexicoGrupo Marlaw S.A. de C.V.

Contact: Lawrence O'Reilly

Heraclito 327A P.B.

Col. Polanco, 11560, Mexico, D.F.

United Kingdom - Republic of IrelandMaynard Chamberlain Associates Ltd.

Contact: Jon Lougee

Bryncerni, Cross Inn, Llanon

Ceredigion, SY23 5NE, United Kingdom

EuropeAlfa Products Srl

Contact: Daniel Silvers

Viale Papiniano 10

20123 - Milano, Italy

Chinahanghai Ye Yuan Trade Co., Ltd.

Contact: Xie Rong Guo

No. 5, 103 Lane, Si Zhuan Road

Song Jiang District, Shanghai, 201613, China

KoreaASKOS Technology, Inc.

Contact: Robert Kihong Kim

1 International Blvd. #400

Mahwah, NJ, 07495, USA